Enhancing Resource Tracking and Optimising Mining Practices

Overview

Our advanced solution automates the identification and authentication of mineral-carrying vehicles, significantly reducing turnaround time and boosting production efficiency. By reconciling mineral dispatch quantities with e-governance systems, we minimize the risk of en-route pilferage. Our platform delivers comprehensive, statistical insights into mineral transportation activities, categorized by mineral type, grade, area, lease, and transporter. Seamlessly integrating with centralized legacy and ERP systems, our system minimizes the need for manual intervention, ensuring streamlined operations.

Key Feature

Flexible Deployment

Supports on-premises or cloud deployment with the latest architecture.

IoT Sensor Compatibility

Works with RFID, GPS, load, and positioning sensors over LTE/5G, Wi-Fi, and LoRaWAN networks.

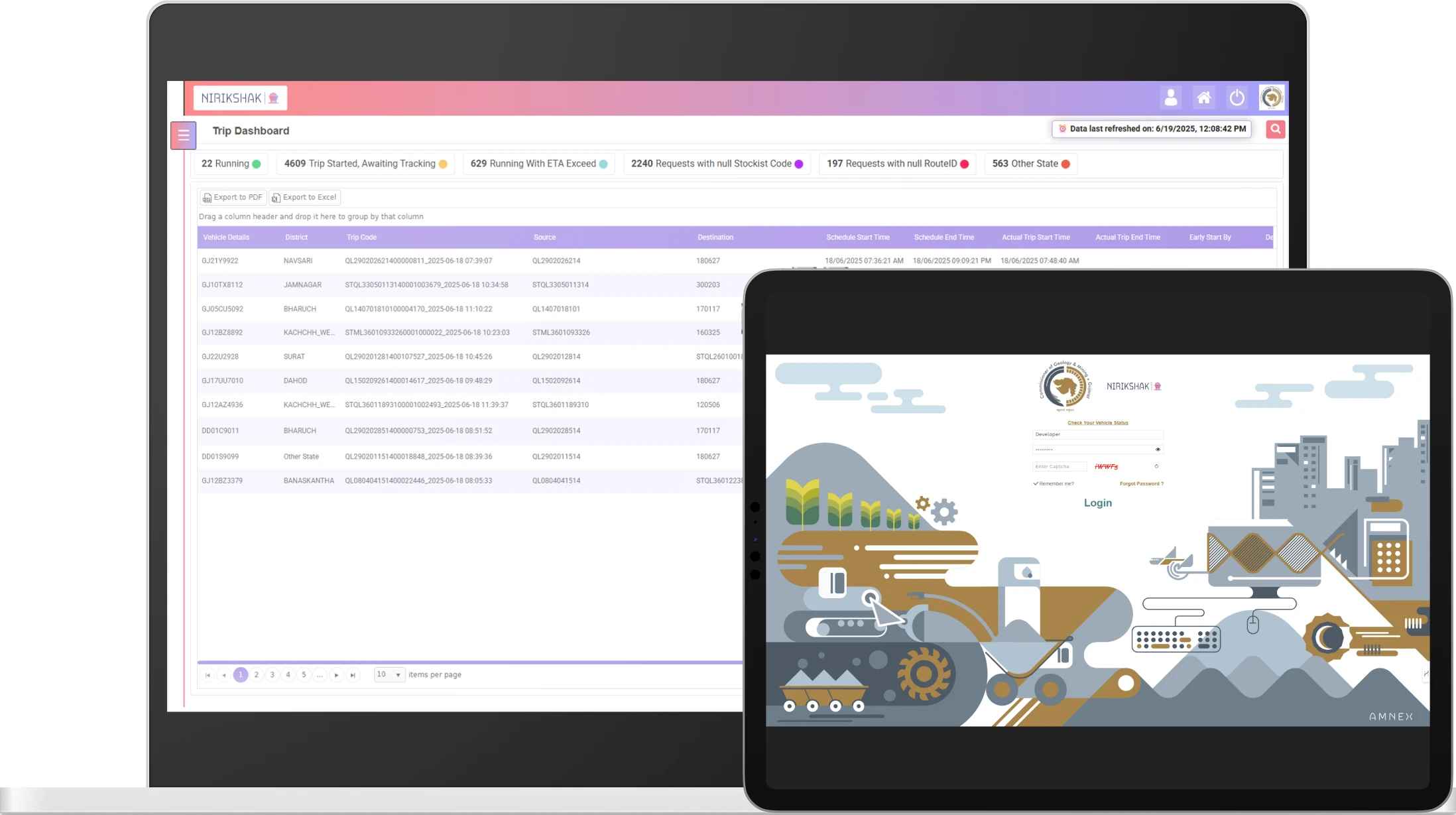

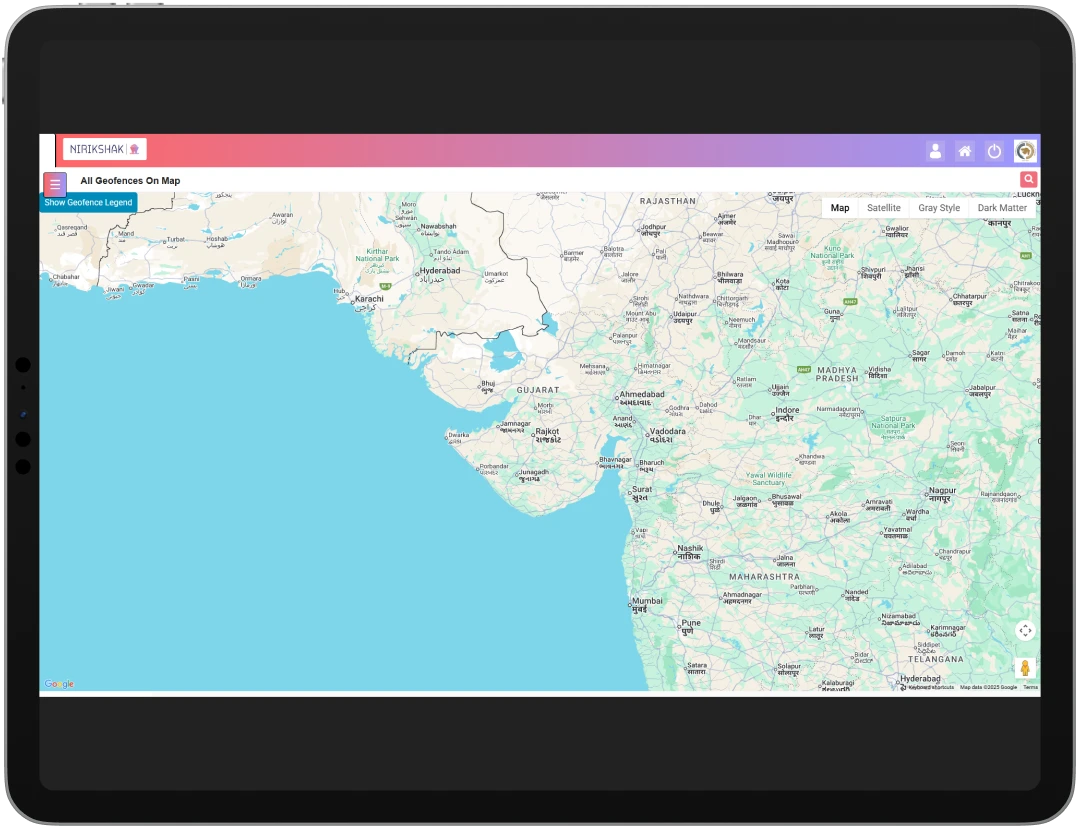

Real-Time Vehicle Tracking

Displays vehicle movement on GIS maps with dynamic monitoring and route deviation alerts.

Automated Operations

Streamlines weighbridge and mine gate processes, reducing delays and manual tasks.

Incident Logging & Response

Logs incidents and coordinates quick responses to accidents or blockages.

Seamless System Integration

Connects with state systems and IoT sensors for automated data acquisition.

Real-Time Alerts & Security

Sends SMS, email, and WhatsApp notifications with mobile access, historical analysis, and robust security.

Benefits

Real-Time Vehicle Tracking

Monitors mineral vehicles with incident management to reduce TAT.

Automated Authentication

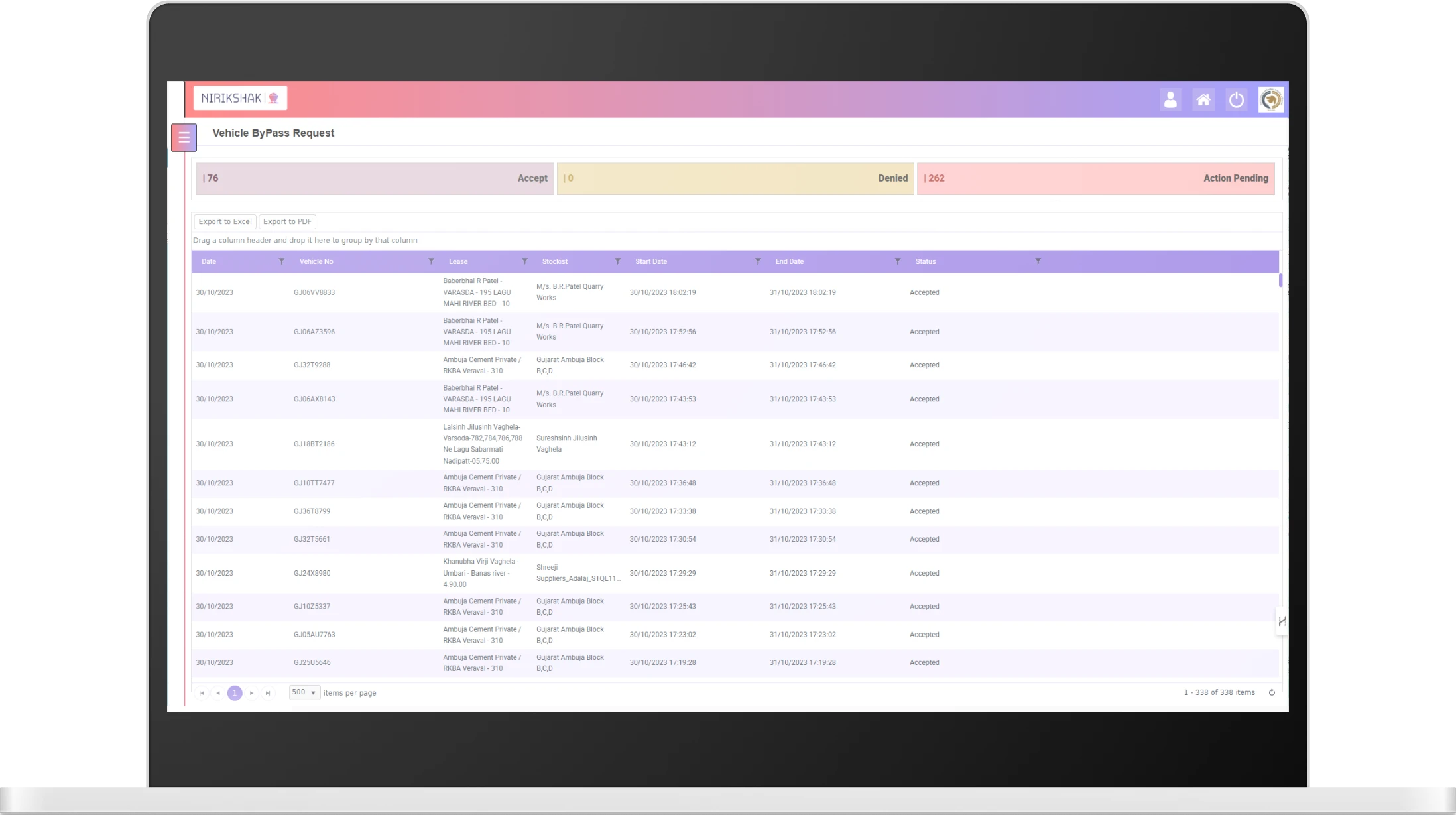

Tracks weighbridges and gates with faster processes and optimized resources.

AI/ML-Driven Scheduling

Optimizes shifts, equipment, and workforce for production planning and HSE compliance.

Centralized Dashboards

Enhances transparency, decision-making, and control via the Integrated Mine Command & Control Center.

Efficient Dispatch & Compliance

Simplifies mineral dispatch reconciliation, enables real-time hazard response, and curbs illegal mining.